- Continue Shopping

- Your Cart is Empty

How are vinyl decals made?

Vinyl stickers aren't the same thing as the paper stickers you pick up in your local stationery store. Vinyl comes with adhesive on one side rolled on top of a backer paper on a big cardboard roll. Every decal we cut is done just how it sounds: we load a roll or piece of vinyl into our cutter, compile the designs to be cut, and the cutter literally cuts the design.

This process is also why multi-color decals are not normally available, and then even only in limited quantities. For each color in that decal, we cut a piece of vinyl and have to hand-place each piece of the decal in place.

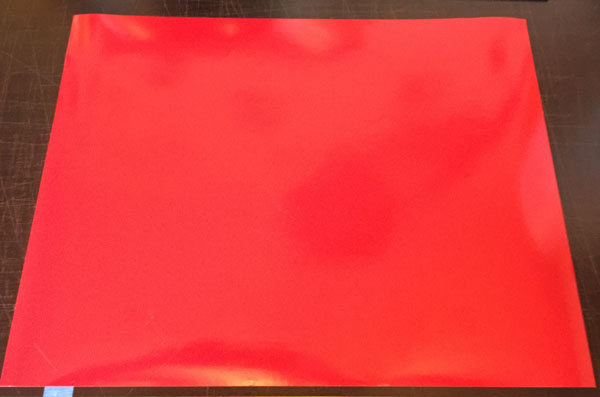

You may not be able to see it, but this piece of vinyl has designs cut into it.

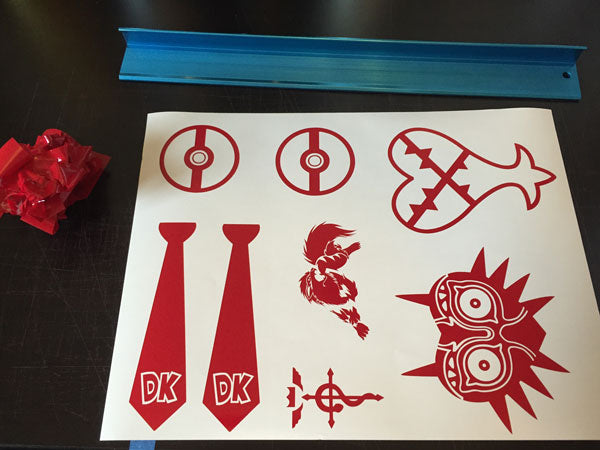

Through a process called weeding, where we pick out the vinyl that's not part of the design, the decal begins to take shape.

On a larger sheet of vinyl like this, it's usually easier to break it up into smaller chunks in order to avoid damaging the decals.

This is a fully-weeded set of decals with the actual weeded vinyl over to the left (the crinkly pile of red vinyl).

Once the decals are fully weeded, we place transfer tape on top and cut the decals apart into their individual designs. Here's a hyperlapse of the entire process on a single sticker: